These are all standard features on Arrow bobtails. If there are features that are not listed here, but you would like included on your bobtail, just ask. Arrow can accommodate almost any request. Check out the optional features available.

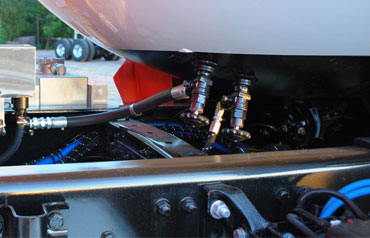

Chassis connections mounted in a central location. Electrical distribution with fuses and relays, RF receiver, and pressure switches. Blue split loom identifies Arrow wiring throughout the bobtail.

Dual 50 watt docking lights mounted midship on front fender with 55° projection angle and interior rock guards (not shown).

Voltage for the LED light fixtures with anti-theft rings is supplied by molded wire harnesses with plug and seal connections for extreme durability and accessibility.

High mount LED stop and turn lamps with a combined 200 watts in stadium work lights on the back of the trucks provide the ultimate visibility.

3″ Spray Fill includes 3″ coupling welded in tank with 3″ back check (liquid capacity = 297 GPM @ 5 PSIG differential pressure).

2″ Liquid Controls meter with LCR II electronic register. Includes electronic temp compensation, 2-stage valve for accurate preset delivery, and cab mounted slip printer.

Slip printer mounted in cab is included with the standard LC meter and LCR2 electronic register package.

Your choice of RF remote system with rechargeable lithium ion battery and 12 volt DC charger.

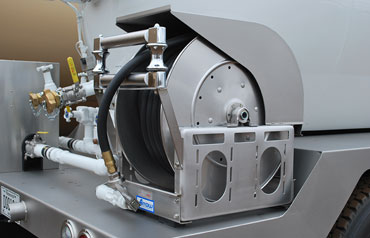

Hose reels in stainless steel or aluminum construction include double captive or Guidemaster hose roller, Polar-Flex delivery hose, quick acting valve, and stainless steel hose end swivel.

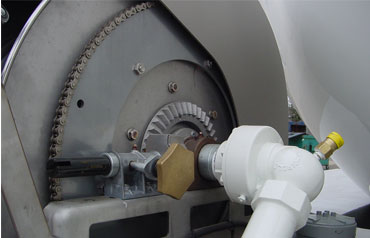

Ultimate performance and durability with brass a pinion gear and #40 chain/sprockets.

Greaseable large diameter inside and outside bearings facilitate low friction and long life.

Heavy duty explosion proof 2/3 HP motor with stainless steel shaft receives voltage from corrosion resistant molded cable. Extra measures that ensure superior performance and awesome longevity in any environment.

Internal pump discharge (IPD) places the majority of discharge piping inside the tank. Added benefits are safety, cleanliness, and lower costs for future remounts. Piping for the pump discharge and re-entry to the tank is accomplished with a single piece of die formed 2 inch schedule 80 pipe. Each end of the pipe is welded to flange connections for added serviceability and to minimize leaks. Internal valve (ISC) is actuated by a brake chamber. Over 20 years ago we began using this design with great success. Chambers have proven to be an extremely durable and reliable under chassis component despite long term exposure to the harshest elements.

PTO shaft assemblies are shielded and telescoping with splined slip sleeves. Grease zerk fittings are provided on the complete PTO shaft assembly for lube maintenance of the u-joints, slip yoke, slip sleeve, and pillow block bearings. The flexible guard cones at each end can be pulled back for access to the fittings.

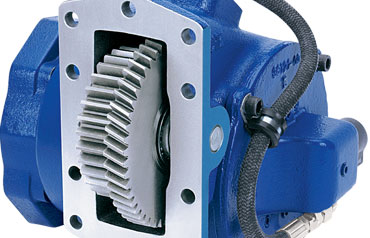

Muncie PTO’s with internal clutch shift are standard equipment to drive the PTO shaft and product pump. Direct engagement of the PTO is accomplished via air toggle switch and/or RF remote. Shutoff valve is installed to isolate pump discharge piping from meter inlet and external bypass piping.

A flexible connector absorbs twisting irregularities between the chassis and deck. Butt-weld long radius 90° elbow promotes smooth flow into the meter.

Meter discharge piping includes stainless steel ball valve (flanged body) with flexible connector and swivel adapter.

Carburetion fittings on Arrow bobtails are commonly utilized for LP alternative fuel injection and heat-exchangers. Both liquid and vapor carb fittings are standard on Arrow bobtails.

Standard location for the easy-to-read flange mounted visual float gauge is in rear head. Options include recessed mount located in a variety of positions.

Rear bumpers fabricated from rectangular tubing meet or exceed DOT rear-end tank protection requirements. The bumper face is made with stainless steel to ensure survival among the unforgiving sodium chloride ice melt and constant battery of road debris.

Two heavy duty tow hooks are welded to the bumper frame.

Manufactured from structural steel channel our vessel tie-downs meet or exceed DOT supporting and anchoring requirements.

Front tie-downs assemblies are specifically engineered with an anti-shift feature to limit movement and account for added stresses due to impact in the event of an accident.

Material thickness and finish are very important considerations with regard to performance and long term surface refurbishing. Arrow Tank’s models are engineered to last the lifetime of the tank and look good as new for the duration.